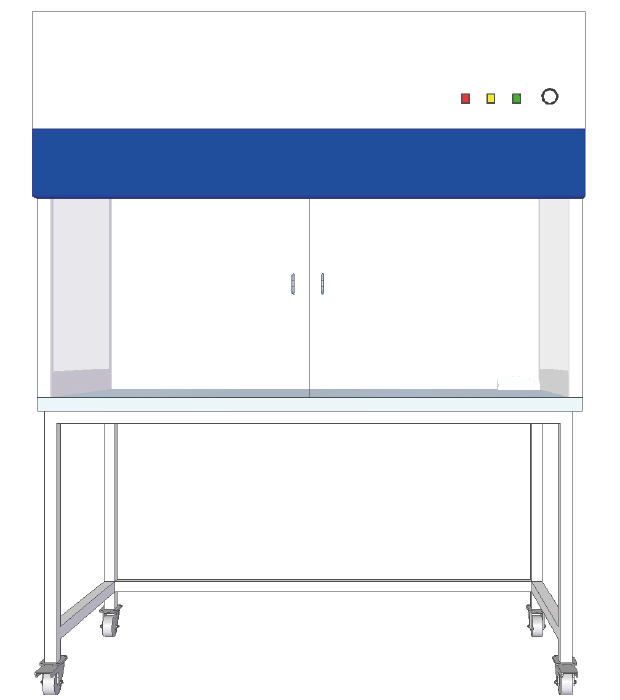

Laminar flow cabinets are particle free, sterile working environments that allow product protection. Ambient air is taken in via a blower across a pre-filter; this air is then forced through a High Efficiency Particulate Arrestor (HEPA) filter that captures particles at an efficiency af 99.99% at 0.3 microns. The air that exits the HEPA filter is clean and unidirectional. As the cabinets are positively pressured, there is no chance of contaminants entering the cabinets. Laminar flow cabinets or clean benches as they are also known, were developed in parallel to clean room technology. It is therefore a mini clean room that allows the manipulation of smaller sized products.

Common industry segments that use laminar flow cabinets include: Electronics, Manufacturing, Testing, Biotechnology, Tissue Culture, Agro-biotech and Pharmaceutical.

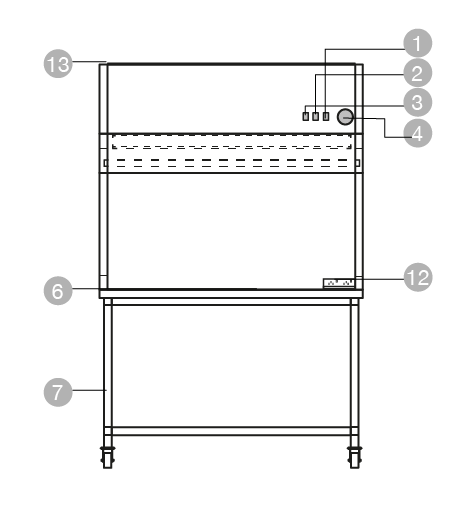

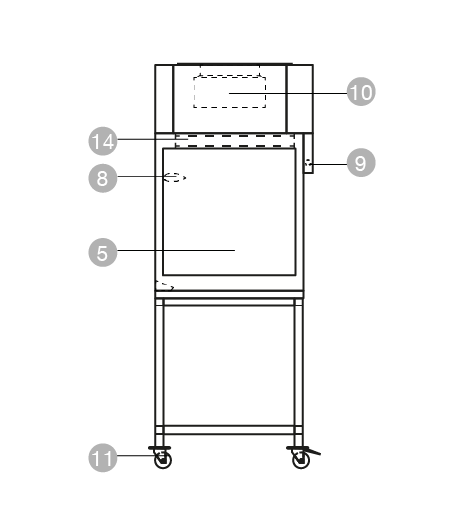

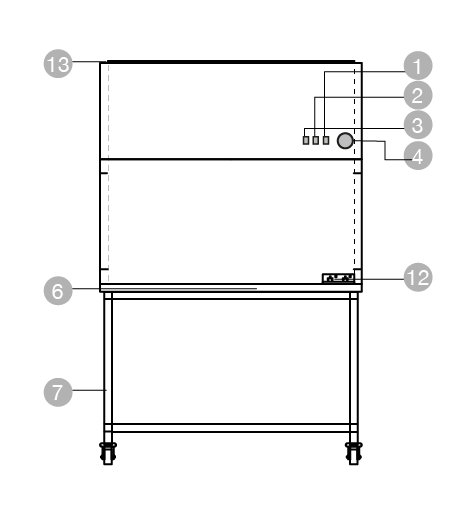

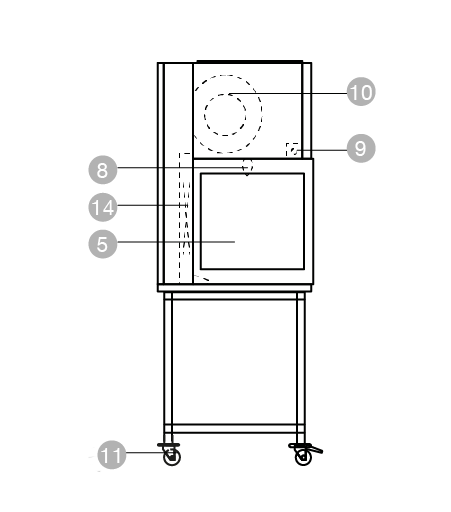

Advancelab manufactures laminar flow cabinets with unique design features that further enhance performance and ensure that maximum product protection is achieved.